The number of jobs available in metal fabrications depends on the type of work they do. Typically, a worker will have to do tasks such as cutting, forming, and welding. As a result, they will have to have certain qualifications. In addition, they will also have to be aware of the working environment. It is important for them to learn more about how to perform their job and how to make the best use of their skills.

Qualifications To Become A Metal Fabricator

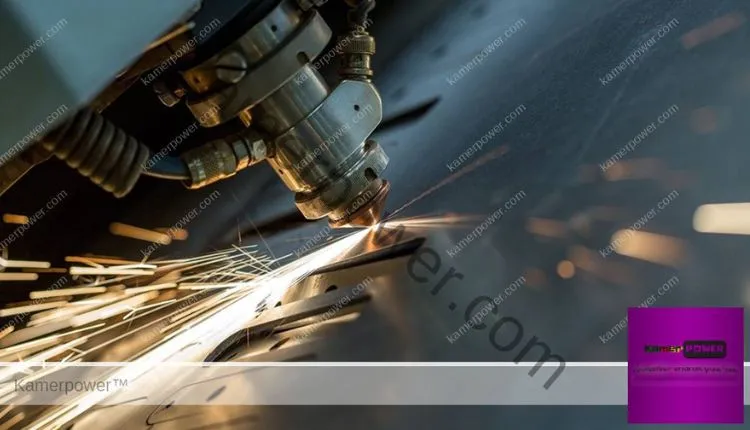

Metal fabricators use a variety of tools to cut, bend, and join metals. They often collaborate with other tradespeople, such as machinists, engineers, and mechanics. In addition to these skills, they need to have a good understanding of metals, their properties, and how they work together. One of the first things you’ll want to do is find out more about the metal fabrication industry. You’ll also want to learn about the different tools and equipment used by fabricators.

If you’re interested in getting started as a how many jobs are available in metal fabrications, you can enroll in an apprenticeship program. This is a great way to earn as you learn. Once you’re proficient, you can apply for a job as a technologist, engineer, or technician. You can also become a metal fabricator without formal education. However, employers usually require at least a year of experience. Those with prior experience can enroll in an apprenticeship program at a local trade school.

Job Duties

Metal fabrication jobs require a high level of education and on-the-job training. If you are motivated to develop professionally, you can enjoy a rewarding career. Fabricators use power tools to create structures from raw metal. Their job includes preparing metal stock for fabrication, cutting bevels and other irregular edges, and bending metal sections. The process may also involve welding or assembling finished products.

These workers are required to wear protective gear, such as steel-capped boots. They must also wear welding masks and safety glasses. These workers also have to perform quality control inspections. They must know how to read and measure parts for accuracy. In addition, they must be able to measure overall steel framing dimensions accurately.

These jobs can be extremely physically demanding. Usually, they are required to work in cramped areas and lift heavy objects. Although this job requires a great deal of physical strength, it also involves high levels of mathematical and computer knowledge. This includes an understanding of blueprints and manufacturing processes.

Earning Potential

Metal fabrications jobs are an excellent choice for those looking for a rewarding career. The field offers many perks and benefits, including excellent salaries and a steady supply of work. A career in metal fabrications requires a combination of skills, technical knowledge, and experience. Some metal workers are self-employed, while others work for large manufacturing companies. However, the industry is expected to grow by billions of dollars by 2027. Whether you’re an employee or an entrepreneur, you’ll have an opportunity to make your mark in the industry.

There are various careers in the industry, ranging from heavy machinery operation to designing and building finished products. To be successful, you need to have a good knowledge of metallurgy, engineering, and math. Some jobs require only a high school degree, while others may offer an apprenticeship or on-the-job training. Depending on the company, you may be able to receive tuition reimbursement, which can be very helpful if you’re paying for your education on your own.

Work Environment

How many jobs are available in metal fabrications offers a wide range of opportunities and a varied work environment. Some metal fabricators roll out thousands of commodity parts every day. Fabrication shops are equipped with automated machinery. They often use CNC equipment, which is used to cut, shape, and assemble sheet metal. These workers need to be very skilled in order to operate these machines.

To ensure safety, workers need to wear personal protective gear. It is also important to follow proper procedures and rules. Employers should provide employees with safety training, which will help prevent common workplace injuries. Metal fabrication is a physically demanding profession. Workers are required to stand for long periods of time and use heavy equipment. Many of these employees may work up to 44 hours a week.

To avoid accidents, metal fabricators should be very careful when using hand tools. This includes checking their suitability for the job at hand. Safety signs and hazard symbols are useful to remind employees of appropriate procedures.

Last Word

So, if you’re looking for a job in metal fabrication, there are many different career options to choose from. Many of these positions offer high salaries and a great work-life balance. In addition, there are also entry-level jobs available for people who don’t have a college degree. Then, visit here https://yijinsolution.com/